Circular Arc Pulley Maintenance Tips for Longevity and Performance

Circular arc pulleys play a crucial role in the smooth operation of many mechanical systems, from conveyor belts to machinery drives. These specialized pulleys are designed to reduce friction and ensure smooth power transmission, making them essential in various industries, including automotive, manufacturing, and robotics. However, like any mechanical component, circular arc pulleys require regular maintenance to ensure they continue to perform at their best and last for years.

In this blog post, we’ll explore practical maintenance tips to extend the lifespan and enhance the performance of circular arc pulleys. We’ll also highlight how companies like Hetuoda Machinery Manufacturing, known for their high-precision transmission parts, are key players in providing top-quality pulleys and other mechanical components for industries worldwide.

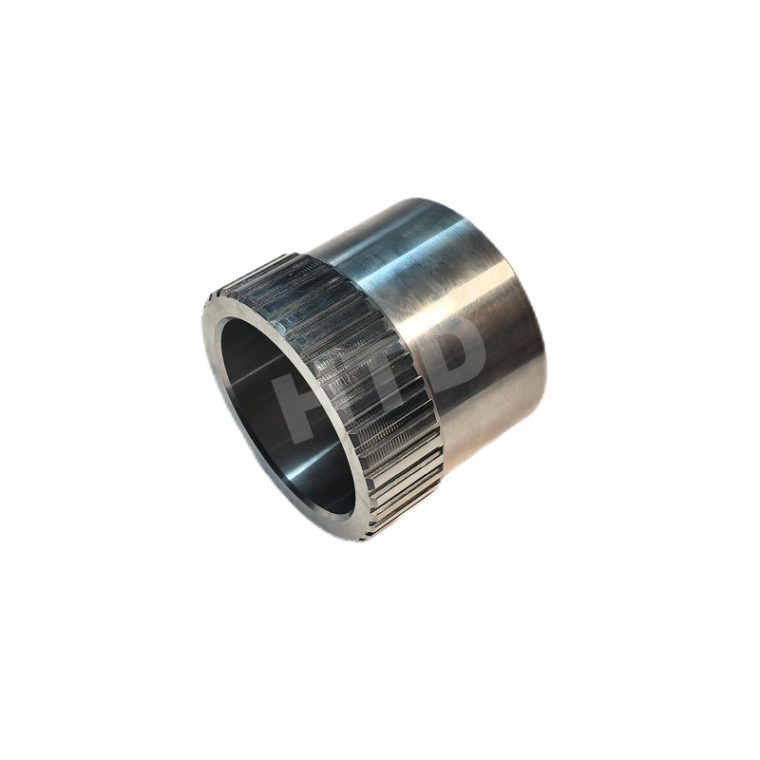

What is a Circular Arc Pulley?

A circular arc pulley is a specialized type of pulley that features an arc-shaped groove on its surface. This design helps to distribute the load evenly and reduces wear, which in turn enhances the efficiency of the system. Circular arc pulleys are typically used in synchronous belts, timing belts, or conveyor systems, where smooth and efficient power transmission is essential.

Importance of Regular Maintenance

Proper maintenance of circular arc pulleys is essential for ensuring optimal performance and preventing unnecessary breakdowns. Regularly maintained pulleys can significantly extend the lifespan of the machinery they are a part of, reduce downtime, and enhance operational efficiency.

Circular Arc Pulley Maintenance Tips

1. Inspect for Wear and Tear Regularly

Like any other component, circular arc pulleys experience wear and tear over time. It's important to inspect the pulley regularly for signs of excessive wear, cracks, or grooves. Check the pulley for:

-

Surface degradation: Look for visible signs of wear on the pulley surface, such as cracks or pitting.

-

Groove alignment: Ensure that the grooves in the pulley are well-maintained and free from any damage that could cause improper belt alignment.

If any of these issues are detected, it’s best to replace the pulley or address the issue promptly to avoid further damage to the system.

2. Clean the Pulley and Surrounding Area

Dirt, dust, and debris can accumulate on the pulley and the surrounding system, which can negatively affect the performance of the circular arc pulley. Regular cleaning is essential to maintain smooth operation. Use a soft cloth or brush to remove any dirt from the pulley’s surface and surrounding areas. Ensure that the belt teeth and the pulley groove are also clean, as debris can cause slippage, increased friction, or misalignment.

When cleaning, avoid harsh chemicals or abrasive tools that could damage the surface of the pulley or belt.

3. Ensure Proper Alignment

Incorrect alignment is one of the most common causes of premature wear on circular arc pulleys and belts. Regularly check the alignment of both the pulley and the belt to ensure they are functioning correctly. Misalignment can lead to uneven wear, slippage, and eventually system failure.

If the pulley appears misaligned, it’s crucial to adjust its position to restore proper function. This adjustment will reduce stress on both the pulley and the belt, improving the overall efficiency of the system.

4. Lubricate for Smooth Operation

Lubrication is essential for reducing friction and ensuring smooth operation of circular arc pulleys. Lubricating the pulley system helps to prevent overheating and extends the lifespan of the components. Use the manufacturer-recommended lubricant to maintain smooth contact between the pulley and the belt. Be careful not to over-lubricate, as excess lubrication can attract dust and debris, which may cause other issues.

5. Monitor Belt Tension

Proper belt tension is vital for the efficient operation of circular arc pulleys. Over-tightening or under-tightening the belt can lead to unnecessary strain on the pulley, leading to wear and potential system failure. Regularly check the tension of the belt and adjust it to the manufacturer’s recommended specifications.

If the belt becomes too loose, it may slip, causing inefficient power transmission. If it’s too tight, it can cause undue stress on the pulley, leading to premature wear.

6. Check for Noise and Vibration

Unusual noises or vibrations during operation can indicate issues with the pulley or the system as a whole. Rattling, squealing, or grinding sounds may indicate that the pulley is misaligned, the belt is worn, or there’s an issue with the tension. If you hear any unusual noises, inspect the system immediately.

Vibration issues can often point to an imbalance in the pulley or the belt. It’s important to address these issues quickly to prevent further damage and avoid operational downtime.

7. Replace Worn Components Promptly

Like any mechanical part, pulleys and belts have a limited lifespan. If you notice significant wear on the pulley or belt, it’s essential to replace the worn components promptly. Continuing to use worn-out parts can cause damage to other components in the system, increasing repair costs and downtime.

How Hetuoda Machinery Manufacturing Contributes to Long-Lasting Pulleys

Hetuoda Machinery Manufacturing is a leading provider of high-precision transmission parts, including circular arc pulleys, synchronous pulleys, gears, and other essential mechanical components. The company’s products are renowned for their superior quality, ensuring smooth, efficient performance across various applications.

By using high-quality, durable materials and advanced manufacturing techniques, Hetuoda produces precision-engineered pulleys that offer longer lifespans, reduced maintenance requirements, and optimal performance. Their dedication to quality ensures that customers receive pulleys that can withstand the rigors of demanding environments, making them an excellent choice for industries that rely on smooth mechanical operations.

Conclusion

Circular arc pulleys are vital components in many mechanical systems, and maintaining them properly is essential for ensuring they continue to perform at their best. By regularly inspecting, cleaning, and lubricating pulleys, ensuring proper alignment and belt tension, and addressing wear issues promptly, you can significantly extend the lifespan of your pulleys and reduce the risk of failure.

If you are looking for high-quality pulleys and precision transmission parts, companies like Hetuoda Machinery Manufacturing provide top-of-the-line solutions. Their expertise in producing durable and high-performance components ensures that your systems run efficiently, minimizing downtime and maximizing productivity.

By following these maintenance tips, you can improve the longevity and performance of your circular arc pulleys, ensuring that your machinery continues to operate smoothly for years to come.

- Education

- Course

- Books

- Drawing

- Question

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Programming

- Religion

- Shopping

- Sports

- Curriculm

- Wellness