Understanding the Functionality of Vacuum Emulsifying Homogenizer Mixers in Food and Cosmetic Industries

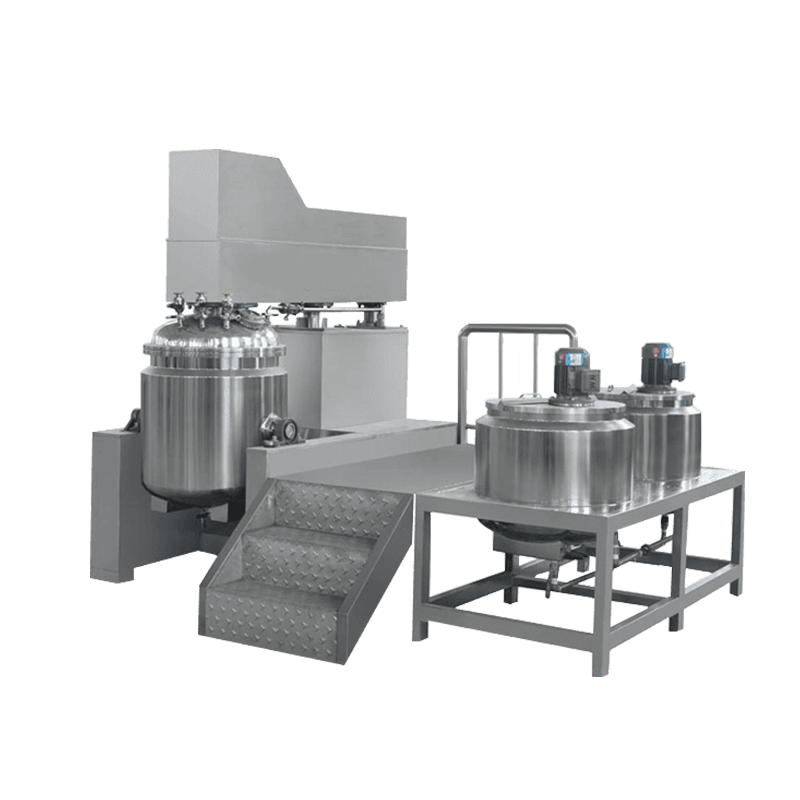

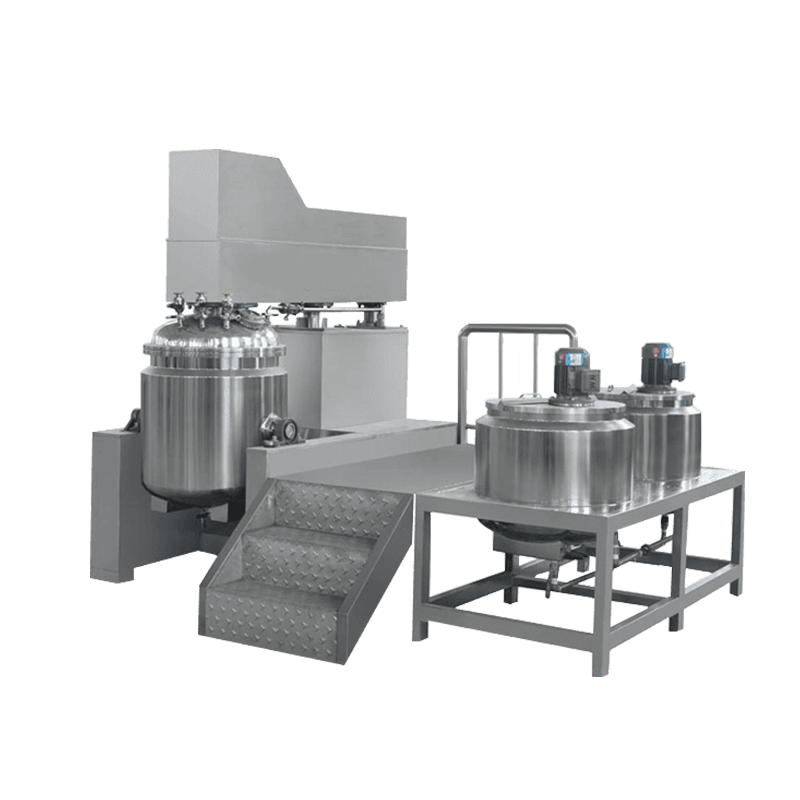

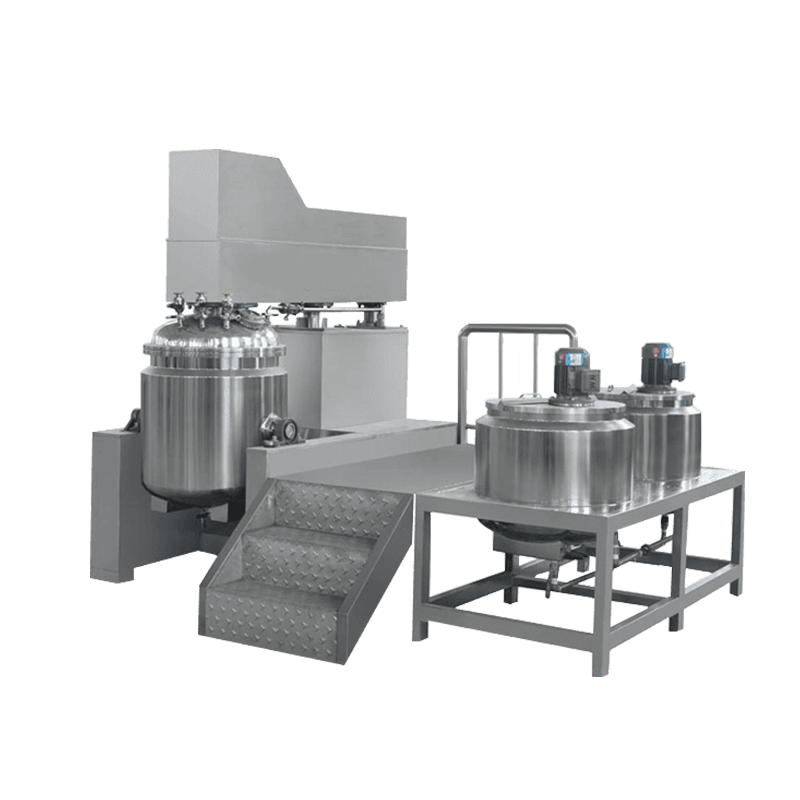

In today’s fast-paced manufacturing world, achieving consistent texture, stability, and quality in food and cosmetic products is a top priority. One essential piece of equipment that ensures high efficiency and precision in the production process is the vacuum emulsifying homogenizer mixer. This advanced mixing system plays a crucial role in industries that require the perfect blending of liquids, oils, and solids into uniform and stable emulsions.

As a leading company in machinery design and manufacturing, Orisun specializes in the production of high-performance vacuum emulsifying homogenizer mixers that meet the needs of both food and cosmetic manufacturers. In this blog, we’ll explore the functionality, benefits, and applications of these powerful machines and how Orisun contributes to the advancement of modern production processes.

What is a Vacuum Emulsifying Homogenizer Mixer?

A vacuum emulsifying homogenizer mixer is an industrial-grade mixing system designed to create smooth, uniform, and stable emulsions by combining liquid and solid ingredients under vacuum conditions. The machine integrates several key processes, including:

Emulsification – The process of breaking down and blending immiscible liquids (such as oil and water) into a stable emulsion.

Homogenization – Ensuring a fine and uniform particle distribution for improved texture and stability.

Vacuum Mixing – Preventing air bubbles and oxidation, leading to a smoother and longer-lasting product.

Key Components of a Vacuum Emulsifying Homogenizer Mixer

Vacuum System – Removes air and prevents oxidation, ensuring product purity and stability.

High-Shear Homogenizer – Breaks down ingredients into microscopic particles, creating a fine, even texture.

Mixing Tank with Agitator – Facilitates continuous blending of ingredients for a uniform composition.

Heating and Cooling System – Controls temperature to enhance emulsification and prevent product degradation.

Control Panel – Offers automated settings for precision control of speed, temperature, and mixing time.

Benefits of Vacuum Emulsifying Homogenizer Mixers

1. Superior Emulsification and Stability

One of the primary advantages of using a vacuum emulsifying homogenizer mixer is its ability to create ultra-fine emulsions with superior stability. The high-shear homogenization process ensures that oil and water-based components blend seamlessly, preventing separation over time.

2. Enhanced Product Quality

By operating under vacuum conditions, the mixer eliminates air bubbles, reducing oxidation and contamination. This results in smoother textures, increased shelf life, and a more consistent final product.

3. Faster and More Efficient Production

Traditional mixing methods often require multiple steps and extended processing times. A vacuum emulsifying homogenizer mixer streamlines production by combining emulsification, mixing, and homogenization into a single process, significantly increasing manufacturing efficiency.

4. Customization for Different Products

The machine allows for precise control of mixing speed, temperature, and pressure, making it suitable for a wide range of formulations, from low-viscosity liquids to thick creams and pastes.

5. Compliance with Industry Standards

In both the food and cosmetic industries, hygiene and safety regulations are critical. Vacuum emulsifying homogenizer mixers are designed with stainless steel, sanitary-grade materials, and automated cleaning systems to meet strict industry standards.

Applications in Food and Cosmetic Industries

Food Industry Applications

Mayonnaise and Sauces – Ensures smooth, creamy textures without phase separation.

Dairy Products (Creams and Yogurts) – Enhances consistency and prevents syneresis (water separation).

Chocolate and Confectionery Fillings – Achieves a uniform, glossy finish for premium-quality sweets.

Nutritional Supplements – Enables efficient mixing of vitamins, oils, and active ingredients.

Cosmetic Industry Applications

Creams and Lotions – Achieves a silky-smooth texture with long-lasting stability.

Shampoos and Conditioners – Ensures even dispersion of active ingredients for better performance.

Lipsticks and Foundations – Produces fine, pigment-rich formulations with optimal blending.

Sunscreens and Serums – Prevents clumping and enhances the absorption of active ingredients.

Orisun: A Trusted Partner in Machinery Design and Manufacturing

As a leading provider of industrial mixing solutions, Orisun specializes in designing and manufacturing high-quality vacuum emulsifying homogenizer mixers tailored to the unique needs of food and cosmetic manufacturers. With expertise in precision engineering and automation, Orisun ensures that its equipment delivers:

Cutting-edge technology for superior emulsification and homogenization.

Customizable solutions to meet the specific requirements of different industries.

Durable and hygienic designs that comply with international safety standards.

Efficient production support, including installation, maintenance, and technical assistance.

By integrating advanced vacuum emulsifying homogenizer mixers into their production lines, manufacturers can achieve higher efficiency, improved product quality, and greater cost savings.

Conclusion

The vacuum emulsifying homogenizer mixer is an indispensable tool in modern food and cosmetic manufacturing, ensuring the perfect blend, stability, and efficiency in product formulations. With its ability to eliminate air bubbles, enhance consistency, and streamline production, this advanced mixing system is a game-changer for businesses seeking to improve their product quality.

With Orisun’s expertise in mechanical design and manufacturing, companies can rely on state-of-the-art mixing solutions that meet industry demands for precision, hygiene, and efficiency. Whether in the food or cosmetic sector, investing in a high-quality vacuum emulsifying homogenizer mixer is a step toward superior product innovation and market success.

Applications of Vacuum Homogenizer Mixing Tanks in the Food and Pharmaceutical Industries

- Education

- Course

- Books

- Drawing

- Question

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Programming

- Religion

- Shopping

- Sports

- Curriculm

- Wellness