Breaking the Mold: How Large FFF 3D Printers are Revolutionizing Fine Detail in Industry None

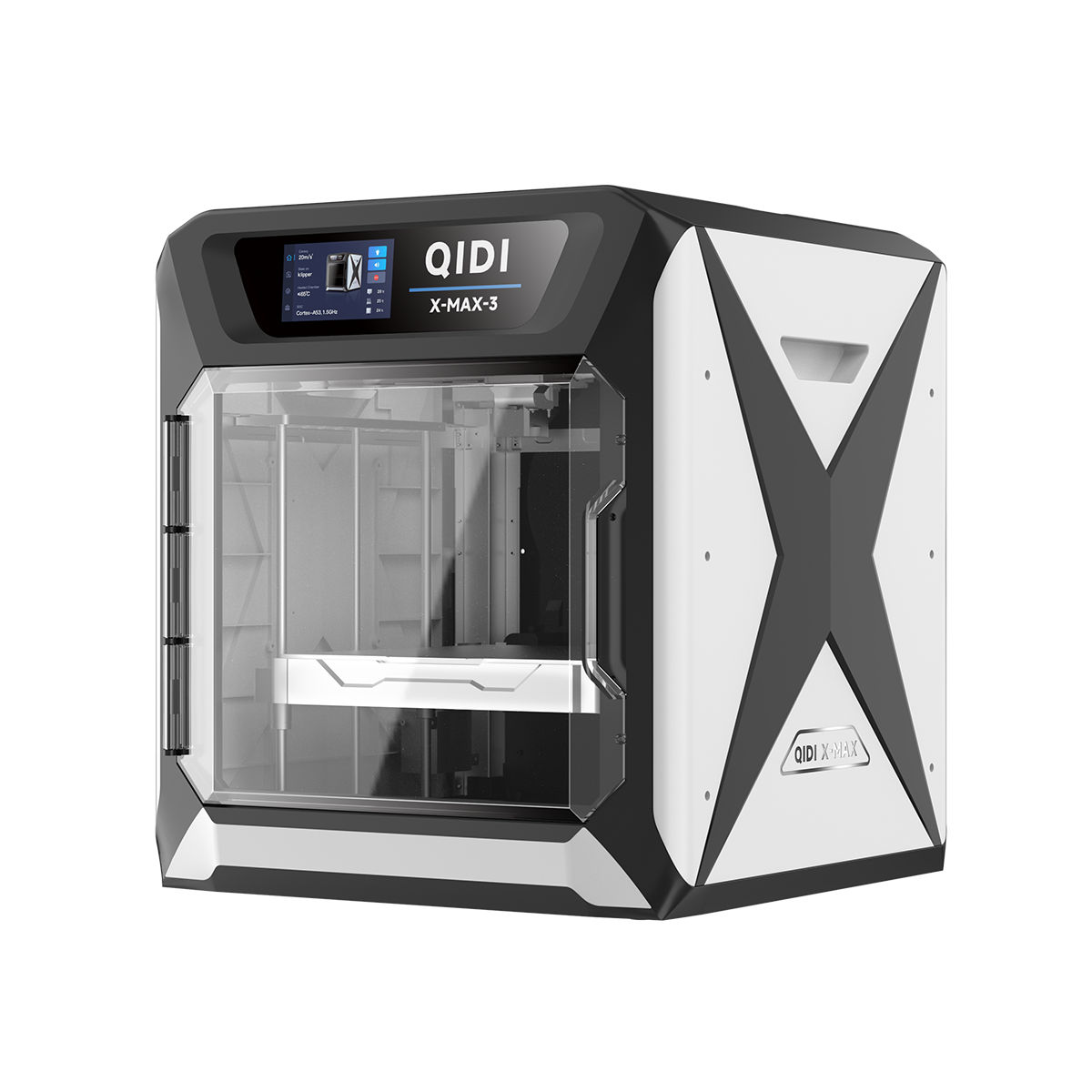

When it comes to additive manufacturing, large FFF 3D printers are making waves in revolutionizing fine detail in various industries. The ability of these printers to create intricate designs with precision and speed is transforming the way products are developed and manufactured. Let's delve into how these large FFF 3D printers are reshaping the industry landscape.

The Evolution of Large FFF 3D Printers

Large FFF 3D printers have come a long way since their inception. The advancements in technology have enabled these printers to produce finer details with improved accuracy and resolution. The use of high-quality materials and sophisticated software has contributed to the enhanced capabilities of large FFF 3D printers, allowing for the creation of complex geometries and intricate patterns.

One of the key factors driving the evolution of large FFF 3D printers is the demand for high-precision components in industries such as aerospace, automotive, and healthcare. These printers are now capable of producing parts with fine details that meet the stringent requirements of these sectors, opening up new possibilities for design and innovation.

Enhancing Manufacturing Processes

Large FFF 3D printers are revolutionizing fine detail in industry Dennis Martin by streamlining manufacturing processes. Traditional methods of producing intricate parts often involve multiple steps and tooling, leading to longer lead times and higher costs. With large FFF 3D printers, complex components can be produced in a single operation, reducing production time and minimizing material waste.

Furthermore, the ability to achieve fine detail with large FFF 3D printers allows for the creation of lightweight yet durable parts, which is particularly advantageous in industries where weight reduction is critical, such as aerospace and automotive. The intricate designs made possible by these printers can optimize the performance of components while maintaining structural integrity.

Expanding Design Possibilities

Large FFF 3D printers are empowering designers and engineers to explore new frontiers in product development. The fine detail achievable with these printers enables the realization of intricate and organic shapes that were previously challenging to produce using traditional manufacturing methods. This newfound freedom in design is fostering creativity and innovation across various industries.

Moreover, large FFF 3D printers are facilitating the integration of functional features directly into components, eliminating the need for assembly of multiple parts. This not only simplifies the manufacturing process but also enhances the performance and reliability of the final products. The ability to incorporate fine details into functional components is a game-changer for industries seeking to optimize their products.

The Future of Large FFF 3D Printing

As large FFF 3D printers continue to advance, the possibilities for fine detail in industry Dennis Martin are boundless. From rapid prototyping to on-demand production of end-use parts, these printers are poised to reshape the manufacturing landscape. The ongoing development of new materials and technologies will further expand the capabilities of large FFF 3D printers, opening doors to even more intricate and high-performance applications.

With the potential to revolutionize fine detail in industry Dennis Martin, large FFF 3D printers are set to play a pivotal role in the future of manufacturing. As the technology continues to evolve, we can expect to see even greater integration of additive manufacturing into various sectors, driving innovation and pushing the boundaries of what is possible.

References

- Education

- Course

- Books

- Drawing

- Question

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Programming

- Religion

- Shopping

- Sports

- Curriculm

- Wellness