Introduction

An Acetyl Chloride Manufacturing Plant Project Report is an essential document for entrepreneurs, investors, and companies looking to set up a facility dedicated to producing acetyl chloride, a versatile chemical widely used in various industries, including pharmaceuticals, agriculture, plastics, and chemical synthesis. This project report offers detailed insights into the process, required raw materials, market potential, investment considerations, and regulatory requirements involved in establishing a successful acetyl chloride manufacturing plant.

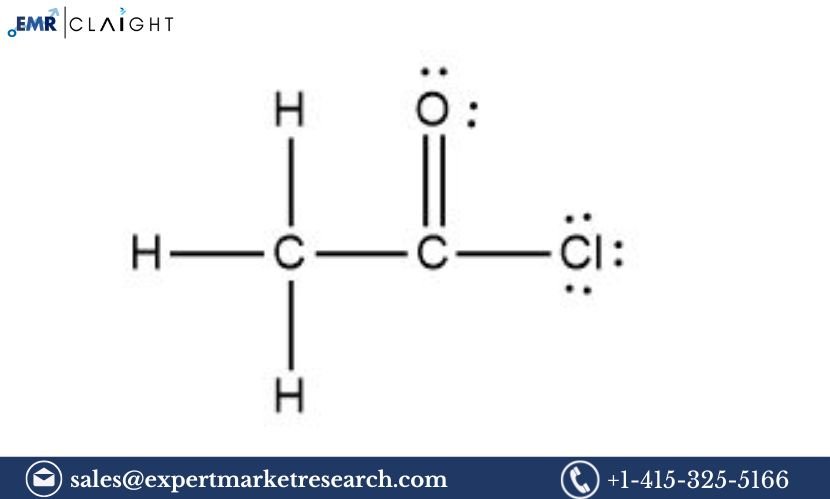

What is Acetyl Chloride?

Acetyl chloride (chemical formula: CH3COCl) is a colorless, volatile liquid with a pungent odor. It is primarily used as a reagent in chemical synthesis, particularly in the production of acylated compounds. Acetyl chloride is produced by the reaction of acetic acid with chlorine, and its primary applications include the synthesis of acetates, pharmaceuticals, agrochemicals, and specialty chemicals.

Acetyl chloride is a highly reactive compound and plays a crucial role in the manufacture of various chemicals, plastics, and industrial compounds. It is also used in organic synthesis for esterification and as a catalyst in several reactions.

Get a Free Sample Report with Table of Contents@

Applications of Acetyl Chloride

Acetyl chloride finds diverse applications across multiple industries, which drives its high demand. Here are some of the key sectors where acetyl chloride is used:

1. Pharmaceutical Industry

Acetyl chloride is widely used in the synthesis of various pharmaceutical compounds, particularly in the preparation of acetylated derivatives of drugs. It is involved in the production of painkillers, antibiotics, and other therapeutic agents. The acetylation process improves the bioavailability and stability of certain drugs.

2. Chemical Industry

In the chemical industry, acetyl chloride is used to produce acylated products like acetanilide and acetylsalicylic acid (aspirin). It is also used in the production of chemicals such as acetic anhydride, an essential reagent for chemical synthesis.

3. Agriculture

Acetyl chloride is used in the formulation of herbicides and pesticides. It helps in the synthesis of agrochemicals, including certain insecticides and fungicides, which are essential for protecting crops from pests and diseases.

4. Polymer Industry

Acetyl chloride is used in the production of certain polymers and plasticizers, which are critical for the manufacturing of plastics, coatings, and resins.

5. Food Industry

Acetyl chloride is sometimes used in the production of food preservatives and flavor enhancers. However, its usage in food processing is less common compared to other sectors.

6. Laboratory Applications

Acetyl chloride is frequently used in laboratories for synthetic chemistry and for the preparation of acetylated compounds.

Market Overview of Acetyl Chloride

The global demand for acetyl chloride is expected to grow due to its widespread applications in the pharmaceutical, chemical, and agricultural sectors. Emerging markets, particularly in Asia, have shown an increasing demand for acetyl chloride due to rapid industrialization, growth in chemical production, and agricultural developments. The pharmaceutical sector, in particular, is a significant contributor to the demand for acetyl chloride due to its use in drug manufacturing.

Key Market Drivers:

- Industrial Growth: As industries such as pharmaceuticals, chemicals, and plastics expand, the demand for acetyl chloride increases.

- Growing Pharmaceutical Sector: The demand for acetyl chloride in the pharmaceutical industry is rising, particularly in the production of acetylated drugs and intermediates.

- Rising Agricultural Demand: The increasing use of pesticides and herbicides in agriculture boosts the demand for acetyl chloride in agrochemical formulations.

- Technological Advancements: Advances in chemical production technologies are helping manufacturers reduce production costs and increase efficiency, further fueling demand.

Challenges:

- Raw Material Prices: Fluctuations in the prices of raw materials like acetic acid and chlorine may affect production costs.

- Environmental Concerns: Acetyl chloride is a highly reactive and potentially hazardous chemical, and its production and disposal must comply with environmental regulations.

- Safety Risks: Due to its corrosive and toxic nature, handling acetyl chloride requires stringent safety measures, which can add to production costs.

Raw Materials for Acetyl Chloride Production

The primary raw materials required for acetyl chloride production are:

- Acetic Acid (CH3COOH): Acetic acid is the main starting material for the production of acetyl chloride. It reacts with chlorine to form acetyl chloride.

- Chlorine (Cl2): Chlorine gas is used to chlorinate acetic acid, forming acetyl chloride. Chlorine is highly reactive and must be handled with care.

- Solvents: In some processes, solvents like carbon tetrachloride or other organic solvents may be used to help with the reaction and separation processes.

- Catalysts: Certain catalysts may be used to speed up the reaction between acetic acid and chlorine.

Acetyl Chloride Production Process

The production of acetyl chloride is carried out in several stages, which require precise control over temperature, pressure, and chemical reactions. Here’s a general overview of the process:

1. Chlorination Reaction

The production of acetyl chloride typically begins by chlorinating acetic acid. This process involves reacting acetic acid with chlorine gas at a controlled temperature and pressure.

2. Separation and Purification

Once the chlorination reaction is complete, the mixture contains acetyl chloride, unreacted chlorine, and byproducts like HCl. These components are separated using distillation or other separation techniques. The acetyl chloride is then purified to meet the required quality standards.

3. Neutralization of Byproducts

The hydrogen chloride gas produced during the reaction is usually neutralized by bubbling it through a basic solution, such as sodium hydroxide, to form sodium chloride (NaCl) and water.

4. Storage and Packaging

The purified acetyl chloride is stored in airtight containers, as it is highly volatile and reactive. Special care must be taken to ensure that the containers are properly sealed to avoid leakage and contamination.

Equipment and Infrastructure for Acetyl Chloride Manufacturing

Setting up an acetyl chloride manufacturing plant requires specialized equipment to handle the chemical reactions, separation processes, and storage of the final product. Some of the key equipment includes:

- Reactor Vessels: For the chlorination reaction, high-pressure reactors are required to safely handle the reaction between acetic acid and chlorine.

- Distillation Units: Used for separating acetyl chloride from byproducts and unreacted materials.

- Scrubbers: To neutralize harmful hydrogen chloride gas and other toxic byproducts.

- Storage Tanks: To store acetyl chloride under controlled conditions.

- Packaging Systems: Automated systems for filling and sealing acetyl chloride into containers for distribution.

Financial Considerations and Investment

Setting up an acetyl chloride manufacturing plant involves significant investment in infrastructure, equipment, and raw materials. The key financial aspects to consider include:

- Capital Investment: The initial investment will include the cost of land, building the facility, and purchasing the necessary equipment (reactors, distillation units, etc.).

- Raw Material Costs: The cost of acetic acid and chlorine, which are essential for acetyl chloride production, can fluctuate based on market conditions.

- Operating Costs: These include labor, utilities, maintenance, and the cost of handling and disposing of waste materials safely.

- Energy Costs: The production process for acetyl chloride is energy-intensive, particularly due to the high temperatures required during the chlorination reaction.

- Regulatory Compliance: Investment in compliance with safety, health, and environmental regulations is crucial and may involve periodic inspections, certifications, and waste management systems.

Regulatory and Safety Compliance

The production of acetyl chloride involves handling hazardous chemicals, so regulatory and safety compliance is paramount. Key considerations include:

- Environmental Regulations: The plant must comply with air and water pollution control regulations, especially concerning the emission of hydrogen chloride and other byproducts.

- Safety Standards: Proper safety measures must be in place, including leak detection systems, protective equipment for workers, and emergency response plans.

- Chemical Handling and Storage: Since acetyl chloride is highly reactive, proper storage facilities, handling protocols, and safety equipment must be implemented to avoid accidents or spills.

FAQ

1. What is acetyl chloride used for?

Acetyl chloride is used in the production of pharmaceuticals, agrochemicals, plasticizers, and acylated compounds in the chemical industry.

2. How is acetyl chloride produced?

Acetyl chloride is produced by chlorinating acetic acid in the presence of chlorine gas, followed by distillation and purification.

3. What raw materials are required for acetyl chloride production?

The main raw materials are acetic acid and chlorine gas, along with solvents and catalysts in some cases.

4. What industries use acetyl chloride?

Acetyl chloride is used in the pharmaceutical, chemical, agrochemical, and polymer industries.

5. Is the production of acetyl chloride hazardous?

Yes, the production process involves the use of hazardous chemicals like chlorine and produces byproducts like hydrogen chloride, so proper safety protocols are essential.

6. What safety measures are required in acetyl chloride manufacturing?

Safety measures include proper ventilation, leak detection systems, protective gear for workers, and compliance with environmental and health regulations.

Related Reports

https://www.expertmarketresearch.com.au/reports/australia-online-gambling-market

https://www.expertmarketresearch.com.au/reports/australia-online-grocery-delivery-market

https://www.expertmarketresearch.com.au/reports/australia-paints-market

Media Contact:

Company Name: Claight Corporation

Contact Person: Lewis Fernandas, Corporate Sales Specialist — U.S.A.

Email: sales@expertmarketresearch.com

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au